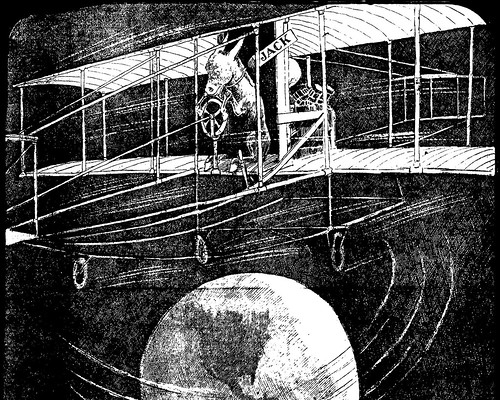

By 1911, the Missouri Mule was uniquely identified with mining as much as a miner, as seen in this illustration from a Joplin paper.

One of the most valuable sources of labor in the early days of the Tri-State Mining District was provided by mules. University of Missouri Professor Dr. Melvin Bradley partnered with the Missouri Mule Skinners Society to produce the Missouri Mule History Project. The project itself was a multi-volume collection of transcribed oral histories regarding the history of Missouri mules. Bradley sought individuals who had experience raising, selling, trading, and working with Missouri mules. One of the individuals he found was Lee Dagley, a native of Joplin, Missouri. The interview is illuminating for several reasons. First, it provides a look at how mules were used in the Tri-State Mining District, but it also allows one to understand life in early Joplin as seen through the eyes of one who lived it.

Lee Dagley was born in Joplin on July 23, 1888, in a small house on what is now today 1817 Michigan Avenue. He was one of thirteen children. Dagley’s parents came to Joplin in the early 1870s and soon found that the “best thing they had was a pick and a shovel and a wheel barrow.” His father bought an acre of land near Sixth and Pearl where the First Presbyterian Church stands. But Dagley’s mother protested and they moved near a large spring on what is today Campbell Boulevard. Growing up, Dagley recalled that Joplin was “all prairie…I herded cattle all over this country.”

According to Dagley, folks in Joplin did not eat much beef when he was growing up. He said, “There’d always be some man in the neighborhood that’d kill a beef and he’d take it around and we’d have beef for a little while. But pork was the main thing.” The family owned one milk cow which provided their milk. Dagley said he pretty much existed on “good milk and bread and butter.” To supplement their income, his family raised and sold chickens and turkeys. Turkeys brought fifteen cents. One turkey that they kept grew to weigh 65 pounds. It was so big and aggressive that Dagley would have to carry a stick to fend it off because of its propensity to attack anyone who came in through their front gate.

At first his father did not know how to mine, but quickly learned, and gained a reputation as “one of the best miners in the country.” But his father was not successful at mining. Still, Dagley recalled that in the early days of mining, miners could only dig 16-18 feet down into the ground before they hit limestone, and water would flood the shaft. Dagley’s father created a sluice trough that washed the lead ore that miners dug out of shallow mines. After washing the ore, someone would pick up the ore and deliver it to the smelter at Granby. Dagley’s father charged miners by the piece and usually made $1 a day. To make additional money, Dagley’s father rented out horses and worked as a “powder monkey.”

Dagley attended school, but quit when he was a sophomore because his father was ill. Dagley took a job at Junge’s Bakery for $3 a week and later $6 a week. He later worked a brickyard, but when the Thomas Mine Royalty Company came to town and offered $1.50 per day to drive a wagon, Dagley left the bakery and began driving a team.

Mining methods in the Tri-State region slowly advanced. Mules would pull cars full of lead ore on the surface, but they also worked below ground. Mules were lowered into the mines, sometimes in a sitting position. According to Dagley, the mines did not use big mules: “They were not big mules. They used small mules. The biggest one would probably weigh 900 lbs.” One particular mule barn that he remembered was “about 60 feet wide and 200 feet long.” The mine operators put “hundreds of tons of hay” in the barn. Dagley boasted, “Oh, this whole country out here was prairie hay, and the best prairie hay that ever was.”

At work, a muleskinner sat “on the front of the car and drive the mule. They’d pull ’em in and they had a track down there…up towards the mill.”

After the turn of the century, however, mines became less reliant on mules. Mines began using steam engines and motors. Mules were relegated to surface work, mainly pulling cars full of ore. The heyday of the mule in the mines of the Tri-State Mining District was over. Mechanization and advancements in mining methods had made them obsolete, but to the men who worked with them in the mines, there would always be fond memories.

* It is worth noting that although this fact was not mentioned in the oral history, Lee Dagley, according to contemporary press reports, was one of the few white men in 1903 who attempted to save Thomas Gilyard’s life from a lynch mob in Joplin.

Thank you for this article. Lee Dagley was my granddad. I grew up in Joplin (Joplin High class of 1960), and he and I spent a lot of time together. Lee and my dad, Neal, made mining machinery at the Dagley Manufacturing Co. during the 1940’s and 50’s, and when I was around 8-12 years old, my granddad would regularly take me with him when he made small deliveries to the big Eagle Picher mine and mill in Picher. Nobody seemed to mind or pay much attention as we wandered around that huge mill while he pointed out some of the equipment he had made, and what function it was performing.

I mowed Mr. Dagley’s yard at his home and business one summer and his son’s as well. He was a great man.